New membrane could make hydrogen transportation cheaper

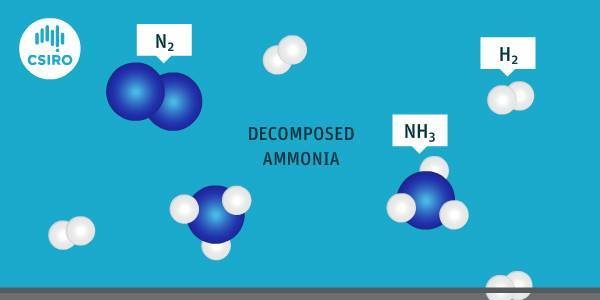

Researchers at the Commonwealth Scientific and Industrial Research Organisation (CSIRO) in Australia have developed a thin metal membrane that can separate high-purity hydrogen from ammonia. The ammonia molecule (NH3) is composed of hydrogen – in fact, hydrogen comprises 17.6% of the weight of the molecule. This makes ammonia an ideal carrier of hydrogen (which can power a range of energy services, including fuel cell-powered transportation).

To move large amounts of hydrogen in its H2 molecular form requires cryogenic liquefaction, which increases the cost and market price of hydrogen. But moving hydrogen as a component of ammonia is potentially much more cost-effective, piggybacking on the ammonia supply chain. Pure ammonia is a liquid under moderate pressure or chilled below -30oC; but can also be stored and transported in a water solution at atmospheric pressure and temperature. The problem is how to separate the hydrogen from the ammonia once its been delivered to the customer. This is where CSIRO’s new membrane reactor technology comes into play.

Over the next two years, CSIRO will develop and demonstrate a commercial hydrogen production unit, capable of supplying 5 kg/day directly from ammonia. The vision is then to package the technology in to modular unit that could be used at a retail fueling station to service hydrogen fuel cell-electric vehicles.

- Full story at Green Car Congress.

- Source: CSIRO. “Case study: Metal membrane for hydrogen separation.” csiro.au, 12 May 2017.

- Image: Decomposed ammonia passes through CSIRO’s metal membrane to produce pure hydrogen (CSIRO).